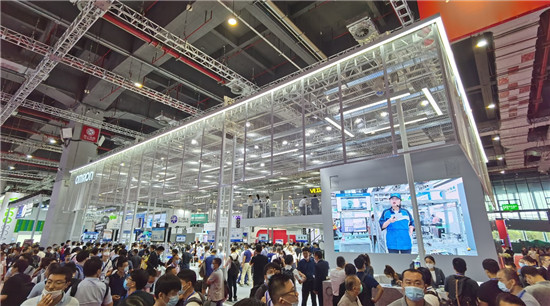

The 22nd China International Industry Expo (hereinafter referred to as "The Expo"), the highly anticipated top event of industrial control industry, has officially kicked off in the National Convention and Exhibition Center (Shanghai).

This year, Omron, together with the concept of "I-Automation! Big Evolution", once again appeared at the China International Industry Fair, showing many of Omron's newly developed cutting-edge applications and technologies. i hope you can personally feel Omron's value creation concept based on industrial Automation "I-Automation!" The present and future of manufacturing innovation.

Opening address

At ten o 'clock in the morning, the grand opening ceremony was held at the stage area of Omron booth. Mr. Odaji, President of Omron Automation (China) Co., LTD., delivered the opening speech, conveying Omron's concept of "i-Automation! Great Evolution" to the media and the audience.

Think of customers' thoughts, solve customers' pain points

Thinking of customers, solve customers' pain points, this is Omron i-Automation! The tenor of evolution. Therefore, this exhibition, we both from the design of the booth and exhibition equipment, are more suitable for the user site, the actual to provide users with solutions and value.

▲ Manufacturing innovation in the post-pandemic era

The novel coronavirus pandemic has swept the world, seriously affecting the global economic development, and brought great impact and challenge to the manufacturing industry. The transformation and upgrading of the manufacturing industry is urgent. In addition to the usual production issues such as labor cost and labor shortage in the past, new issues such as ensuring production safety and avoiding remote production management in production sites with intensive personnel have emerged.

That's why this year we also showcased applications based on AI/IoT/Robot technology that enable customers to ensure high productivity and high quality production without having to rely on a lot of people, or even a lack of people.

After the great field president delivered a wonderful speech, Omron Automation (China) Co., LTD. Automation Technology Center Wang Qi, the minister, and for the audience detailed about the "i-Automation! The origin of "Big Evolution", and the landing of "integrated", "intelligent" and "interactive" in the manufacturing site.

#FormatImgID_1#

i-Automation! Great evolution

In today's manufacturing industry, the shortage of skilled workers, the rising cost of parts in emerging countries, and the unstable supply of products in the face of the global pandemic are becoming more serious.

On the other hand, there is a growing demand for the evolution of various advanced automation technologies (AI, IoT, Robotics, and 5G). In the face of such environmental changes, Omron advocates the concept of manufacturing innovation, which is i-Automation! Through Integrated(control evolution), Intelligent(intelligent), Interactive(new man-machine collaboration) innovative technology, constantly leading the production innovation.

Although i-Automation! Omron is an innovative idea, but most of the innovative applications are created by us and users! So far, more than 170 kinds have been produced and introduced to the manufacturing site. For example: optical parts, assembly process on the counterpoint technology, etc., through the cooperation of flying beat technology and visual feedback technology, solved the previous counterpoint process on the beat, the production beat successfully shortened by 50%!

Site of presentation

After Minister Wang Qi opened the exhibition for the whole [i-Automation! Great Evolution], we officially entered the exhibition equipment. This time, industry experts from various departments of Omron will visually disassemble each part of the equipment for the audience to interpret the core process and value points.

1. Intelligent unit production line of man-machine cooperation

The novel coronavirus pandemic has swept the world, seriously affecting the global economic development, and brought great impact and challenge to the manufacturing industry. The transformation and upgrading of the manufacturing industry is urgent. In addition to the usual production issues such as labor cost and labor shortage in the past, new issues such as ensuring production safety and avoiding remote production management in production sites with intensive personnel have emerged.

In this way, Omron brings advanced technologies such as AI, IoT, MOMA and collaborative robots, and based on big data analysis, the near future production management system is actually applied in Omron's own factory. Through Omron's original automation and intelligence, maximize the exploitation of human potential, to achieve high productivity, flexibility and high quality, strong emergency ability of intelligent unit production line.

2. AI controller x AI Library

The current manufacturing industry is faced with a variety of manufacturing issues, coupled with global crises (such as COVID-19, rainstorms, floods and other natural disasters), we are deeply aware of the importance of quality and safety production, not relying on skilled workers, not limited to on-site production.

In the past, it was necessary to rely on the understanding and experience of skilled workers to carry out regular post-maintenance and improve product quality. Now, AI/IoT technology is used to improve the intelligence of the production site. Through the AI anomaly detection with the maximum 16 dimensional feature quantity, it can predict in advance, detect quality anomalies, and realize the continuous operation of equipment without producing defective products.

3. AI functional examination

Nowadays, with the development of manufacturing industry, we are facing a variety of manufacturing issues, such as labor population reduction, small production of various varieties, local production and local consumption, quality standardization and so on. In addition, there is a growing demand to ensure safe production in response to the current spread of COVID-19 and to avoid the clustering of workers in the same production space.

Omron's newly developed AI functional inspection system can learn the image data of good product status through "AI accurate matching", and acquire the "detection technology and knowledge" accumulated by inspectors in years of practice in a short time. In addition to reproducing the detection ability of skilled workers, compared with the traditional automatic detection method, it can reduce the quality inspection caused by bad work, and make the detection stability 40 times UP.

4, the industry's first Robot integrated control

In the current manufacturing industry, the social problem of the shortage of production labor resources has become more serious due to the impact of COVID-19. Unlike automation, which has been focused on reducing costs until now, there is now a need to reduce the dependence of production on humans as much as possible from the perspective of protecting the personal safety of employees, so the demand for the introduction of robots will continue to rise.

Omron has carried out four innovations for the introduction of robots in the production of multiple varieties through integrated control of the necessary commodity groups such as sensors, controllers, actuators, safety and robots to solve the production difficulties:

1. Automation of manual work is realized through automatic control of robots and peripheral equipment

2. Maximize production capacity

3. Realize the optimal Engineering design before and after the introduction of robots, and innovate Engineering Chain

4. Improve the operation rate (production efficiency) through digitalization and remote countermeasures

Scene pageantry

The Omron will be renamed "i-Automation! "Big Evolution" title, display in recent years Omron developed many applications and technology, i hope you can come to the site, feel Omron based on the industrial Automation business value creation concept "I-Automation! The present and future of manufacturing innovation.