At present, the Chinese government is committed to accelerating the overall transformation and upgrading of the manufacturing industry. After "Internet plus" became a key word in the government work report, "intelligence plus" also became a key concern of the government this year. The report points out that the key area of "smart plus" is manufacturing, and building an industrial Internet platform can effectively expand "smart Plus" and help the manufacturing industry to transform and upgrade to high-end, smart, green and service.

As a manufacturing power, China has many labor-intensive enterprises. However, in recent years, Chinese traditional manufacturing industry is frequently affected, including human cost, environmental cost and many advantages are gradually disappearing. In order to realize the transformation and upgrading of the traditional manufacturing industry, how to solve the problems such as rising cost, manpower shortage and insufficient production efficiency has become the key. Omron has always taken Sensing &Control +Think as the core, integrating "i-Automation! The concept of intelligent manufacturing, launched flexible response to changes in the production scene, the application of a variety of industrial robots to bring production site innovation solutions.

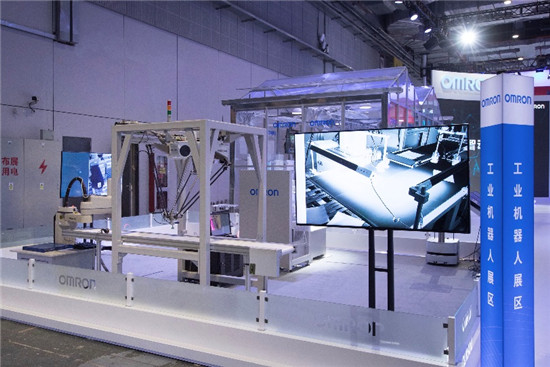

From November 5th to 10th, Omron's FA solution of robot integration appeared again at the second China International Import Expo. The upgraded and iterated high-precision industrial robots constantly broke through the limit of "man-machine integration", truly achieving "what can be done by machines can be done by machines, and people can complete more creative work". It is widely used in food, mobile phone and automobile parts industries.

Omron robot integrated production line

Omron MOMA robot

Food industry

In order to solve the problem of low yield and packing accuracy in the high-speed automatic production line of pork breast, Omron has set 12 Omron Delta Robot(parallel robot), among which 9 Hornet565 parallel robots and 3 Quattro S650h parallel robots. And put forward the solution in the following two aspects:

In terms of system configuration, Omron adopts the control mode of "one drag three" in the raw material belt, which effectively reduces the cost. In addition, the counterweight mode used on the counterweight line allows the robot to show the calibration and modify the point position more flexibly. Compared with PLC and servo system, Omron robot maintenance is more simple and convenient, lower failure rate, and higher productivity.

In terms of control technology, ACE histogram can determine whether there is material stacking. The stacked materials will be sent to the material return area, and the stacked materials will be separated after material sorting and then sent to the robot for grasping. Finally, through the visual function of the robot, it can also judge whether the material is sufficient. When there is no material or insufficient material, the feed conveyor belt stops running.

Hornet565 parallel robot

Quattro S650h parallel robot

Mobile phone industry

As a member of Omron Industrial robots, SCARA robot "hand-in-hand" with FH controller +FH-SM05R camera plays an important role in the mobile phone detection of loading and unloading system -- that is, the robot rotates with the camera for loading and unloading.

In the process of workpiece picking, because of the instantaneous action of the manipulator fixture or sucker, the position of the workpiece is easy to be offset, thus affecting the precision of workpiece placement. In the loading and unloading system, the visual manipulator takes and puts the material, and the powerful motion control ability of FH can realize the effect of 360° high precision takes and puts; At the same time, the position and Angle conversion function of FH controller not only improves the reproducibility and mass production of the program, but also makes the program easier to read and understand.

By using the Omron industrial robot, the working accuracy of the mobile detection and loading system can be controlled within ± 0.1mm. At the same time, all discharge levels of the tray can be given with only one calibration.

SCARA robot

Automobile parts industry

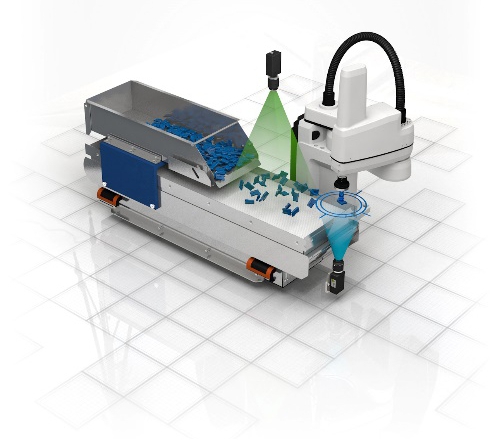

As the core part of throttle body, idle switch has been assembled by manual assembly, resulting in the accuracy and efficiency can not meet the production demand. Omron automates the throttle production line by configuring the eCobra 800 Pro robot, Anyfeeder intelligent loading and unloading vibration disk and vision system.

In this production line, after calibration of the camera-robot coordinate system, the integrated visual architecture of Omron Anyfeeder intelligent feeding system can lock the robot position at a high speed, then obtain the qualified workpiece coordinates in the vibration disc from the locator model, and finally transfer the captured workpiece coordinates to the robot.

After the above steps are completed, the Anyfeeder intelligent feeding algorithm will perform a series of calculations, detect the workpiece density in the vibration disk through gray histogram, and then control the vibration mode of the vibration disk to achieve supply balance.

Anyfeeder intelligent feeding system

In addition to the above three application scenarios, Omron also brings its latest product, MOMA Robot (a combination of collaborative robot and LD mobile robot), to achieve flexible unmanned logistics warehousing through FA technology, to help partners improve overall efficiency.

China is currently in the wave of transformation and upgrading of manufacturing industry, it is not difficult to predict that the future factory will also embark on the road of automation and intelligence, which is in line with Omron's "i-Automation! The ideas coincide. Omron (Shanghai) Co., LTD. (OMS) added a second plant in 2018 and plans to double its capacity from 2017 by 2020. At the same time, OMS will also add industrial robot production lines in the phase I factory. Based on the Sensing &Control + Think core technology, OMS will continue to bring industrial solutions to Chinese customers, making the collaborative production of human and machine a reality.